Our Products

2021 China New Design Automatic Twist Tie Machine/ Automatic Wire Tying Machine - Semi-automatic special Nylon Cable Tie tying Bundling Machine LJL-20 – Lijunle

2021 China New Design Automatic Twist Tie Machine/ Automatic Wire Tying Machine - Semi-automatic special Nylon Cable Tie tying Bundling Machine LJL-20 – Lijunle Detail:

Specification

Model: LJL-20

Type: Non – standard

Power supply: AC 220/110V/50/60HZ

Rating voltage: 300W

Applicable cable tie length 180 / 200mm

The max. tying diameter 40 / 50mm

Max strapping force 15N

Max. conduit diameter 11mm

Productivity 1200-1800pcs/hour

Power 0.75kw

Air pressure 0.6 Mpa

Noise level <70dBA

Starting System Pedal

Suitable area: Special shaped belt

Weight:125KG

Dimension:1200*550*780MM

Suitable

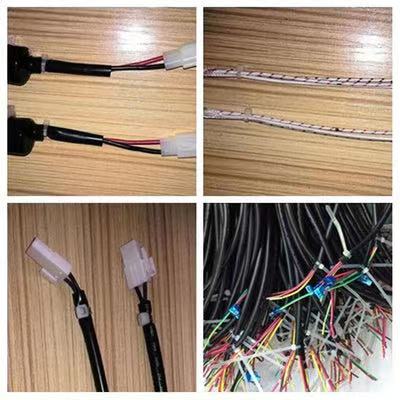

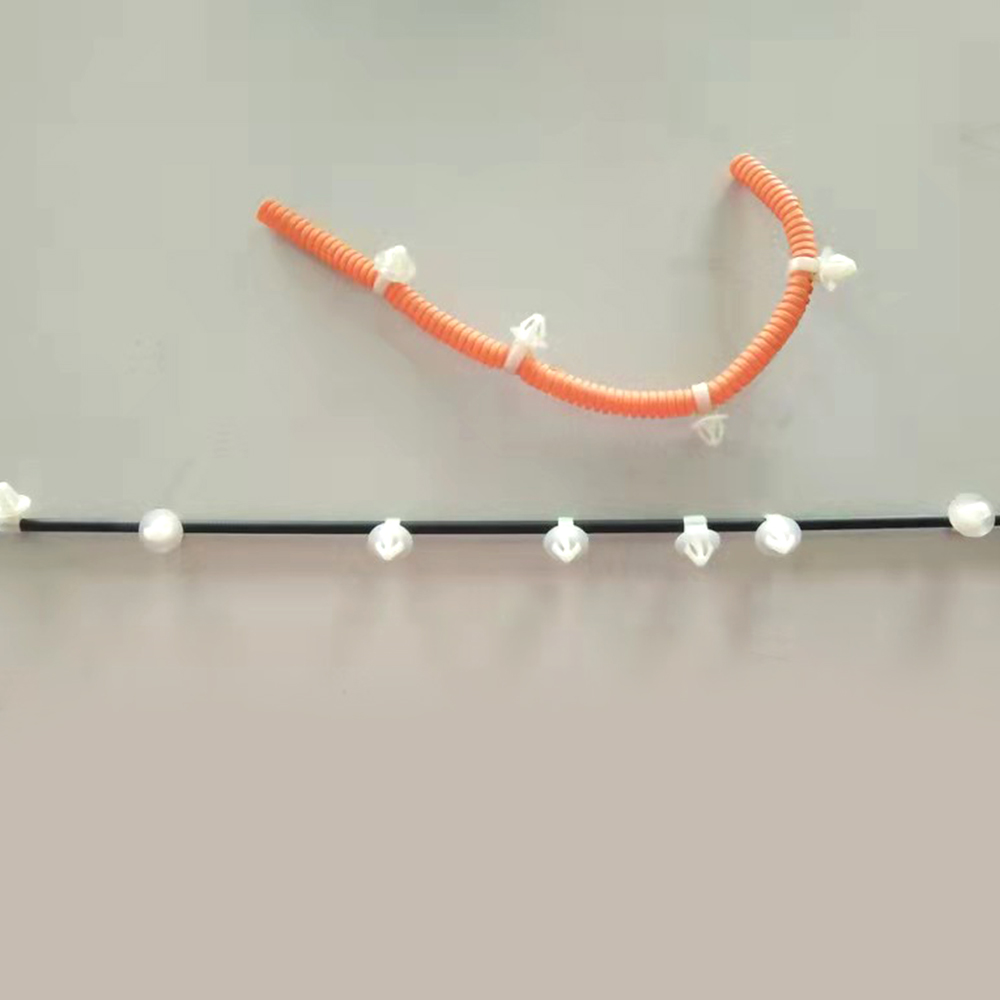

Widely used in electronics factory, bundled TV, computer and other electrical internal wiring, lighting, electrical, electronic toys and other products within the line fixed, mechanical equipment, oil pipeline fixed, the ship on the cable line solid. Car packaging or bundled with other objects, can also be used for wire, air conditioning capillary, toys, daily necessities agriculture, gardening, handicrafts and other bundled items.

Binding wire machine for PLC, text control circuit, working stability is good; , simple and convenient operation, set up and run the related parameter values can be directly in the PLC screen display, clear and intuitive, high degree of automation, good coherence, fast speed, free to set binding wire length, intelligent automation, only need to put around the good material in binding wire mouth, machine automatic induction tie wire, binding wire finish in one second, replace manpower binding wire, solves the manual binding with the tie is not neat, the line size is differ, the slow speed, etc. Reduce damage, reduce fatigue, this device can save more than 30% of the workforce, significantly improve the working efficiency, solved the difficult problem of employment.

Product characteristics

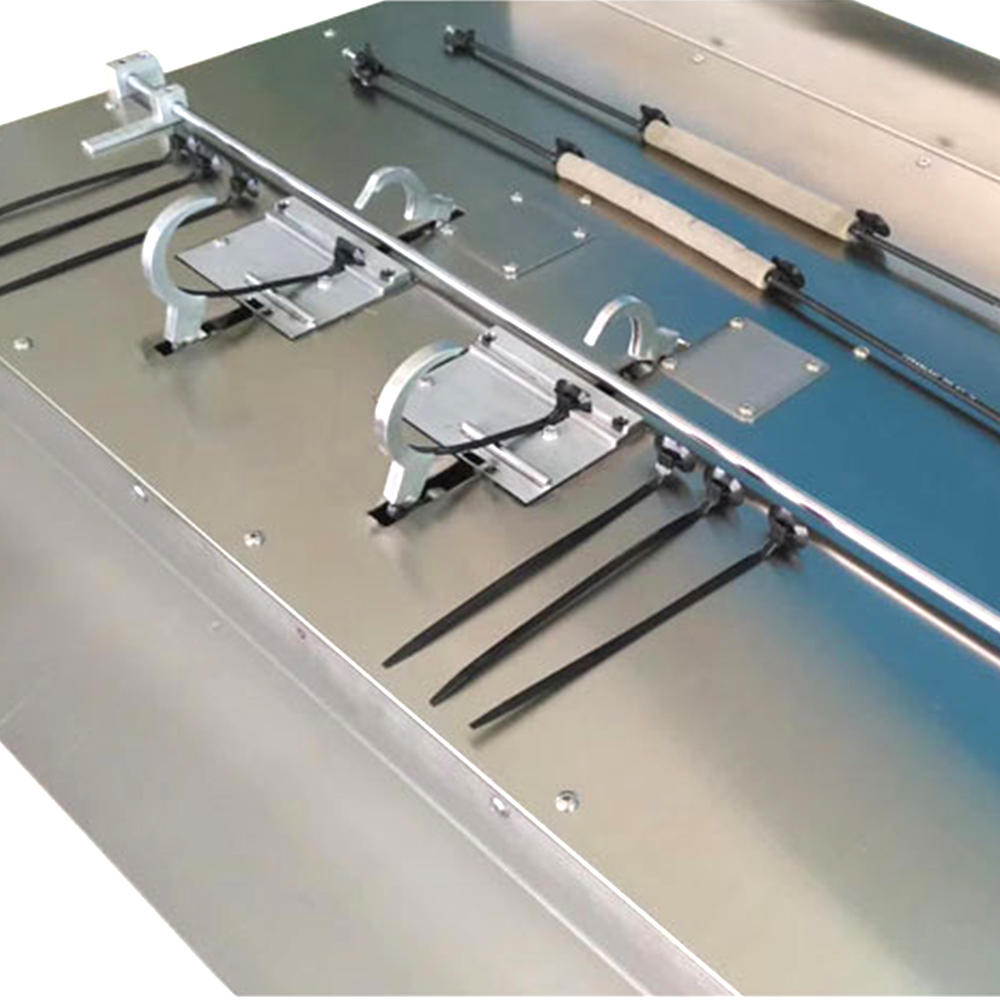

1. The equipment is a non-calibrated machine, and the frame size shall be agreed.

2. Equipment is equipped with a single module bit.

3. Operation operation using foot control.

4. Automatic PLC touch screen control circuit, easy and convenient operation, good working stability.

5. Manual material.

6. Automatic wearing locking strap, automatic cutting tie tape, saving time and effort, improve several times working efficiency.

7. Tie tension touch screen digital adjustment.

8. Tie tail touch screen digital adjustment.

9. No pneumatic.

Third. Main components

1. Control the motherboard (high-speed PCL) 2. Display 3. Step motor 4. Step drive 5. Switch the power supply

6. Sensor 7. Small circuit breaker 8. Guide ook 9. Blade 10. Ropin 11. Pull gear 12. Synchronous wheel

Fourth. Operation sequence:

1. Place in the strap

2. Product placement

3. Press the foot switch and the module completes the tie band, tighten and cut the tail.

4. Remove the product

Product detail pictures:

Related Product Guide:

Adhering to the principle of "quality, service, efficiency and growth", we have gained trusts and praises from domestic and international client for 2021 China New Design Automatic Twist Tie Machine/ Automatic Wire Tying Machine - Semi-automatic special Nylon Cable Tie tying Bundling Machine LJL-20 – Lijunle , The product will supply to all over the world, such as: USA, Belize, Swiss, In the future, we promise to keep offer the high quality and more cost-effective products, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed