Our Products

OEM/ODM Manufacturer Corrugated Tube Cutting Machine Corrugated Tubing Cutting Splitting Machine - Automatic FR4 pcb board cutting machine/pcb lead cutter LJL-903 – Lijunle

OEM/ODM Manufacturer Corrugated Tube Cutting Machine Corrugated Tubing Cutting Splitting Machine - Automatic FR4 pcb board cutting machine/pcb lead cutter LJL-903 – Lijunle Detail:

Description

Model LJL-903

Machine size: 400*400*300mm

Power:110V/ 220V 50HZ/60HZ

Voltage: 60W

Speed:0.-300mm/s

Whole Size: 1500*270*200mm .(Feeding plate can be customized)

Maximum Cutting length: Unlimited

Cutting thickness: 0.6-3.0 mm

Materials:led light strip. aluminum based board, FR-4, glass fibre board and PCB, etc.

Feeding efficiency: 2.5 pcs in a minute(1200mm pcb with 10 pcs pcb board).

Blade material: SKD-11 high-speed steel material from Japan

Storage temperature: -20~50℃

Working temperature: 10~35℃

Limited: the distance between the parts on board and the microgroove should be above 1mm; the side width is unlimited.

Weight: 40kg

Usage:

Be dedicated to the separating of aluminum based light bar, high efficiency, long life, without deformation and burrs, greatly saving labor and improving company benefits.

Features

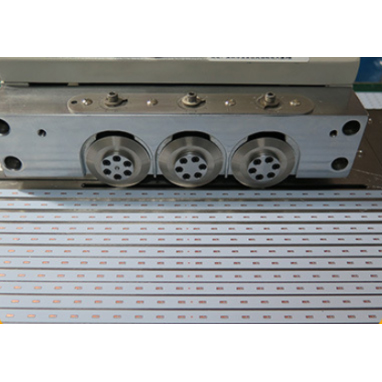

1. The board-cutting is done by 6 blades, and the upside one and the downside one for a cutting unit. So there are Group A, B and C. The whole cutting process is divided into 4 stages. The stress of the cutting process can be reduced by 80% than the traditional one-cut process for the small cutting quantity each time. And the edges of the board are quite smooth after cutting.

2. The cutting process is very stable because of multiple cutting. Even for circuit boards with shallow microgroove.

3. As the low cutting force of the blade, it can prolong the working life of the blades and reduce the cost.

4. Suit for cutting LED aluminum based board, copper substrate, light-emitting tube, light board, display pane, etc.

Product detail pictures:

Related Product Guide:

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for OEM/ODM Manufacturer Corrugated Tube Cutting Machine Corrugated Tubing Cutting Splitting Machine - Automatic FR4 pcb board cutting machine/pcb lead cutter LJL-903 – Lijunle , The product will supply to all over the world, such as: Nepal, Croatia, Comoros, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our products in China!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed